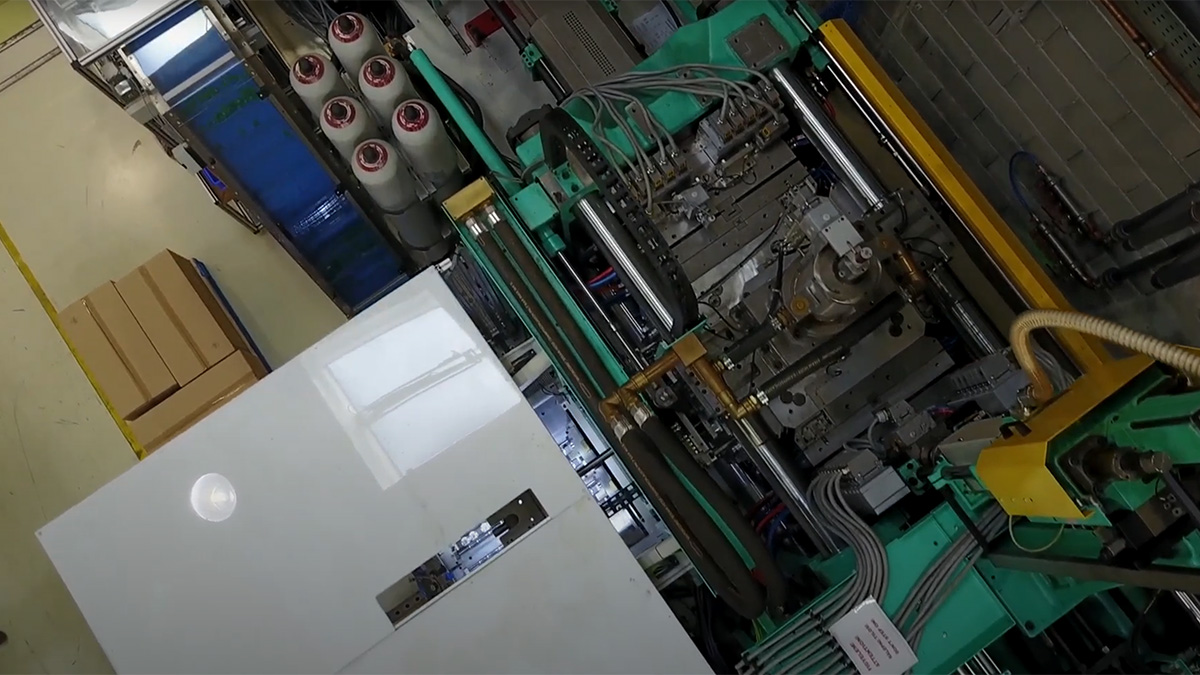

Two-component plastic injection moulding to streamline production by eliminating assembly

With technical advancement come new challenges. We were tasked by a Hungarian subsidiary of a German industrial connector manufacturer to develop a two-component plastic part for one of their products. This injection-moulded component, produced through contract manufacturing, eliminates the need for assembly, offering considerable time and cost savings.